How critical is the timing?

#1

How critical is the timing?

I have a 64 F100 with a 292. It hesitates and stalls when pulling out from a stop, say at a stop sign or a light, or when making a left turn.

I have just rebuilt the carb, replaced the fuel pump, replaced the distributer, installed an electronic ignition unit.

The hesitation seems to be at least in part a function of the timing.

I set the timing to 6 deg BTDC as the manual says. Still does it. I just reset it to 10deg and I am about to test drive it.

The question is how critical is the timing setting if the engine is not pinging?

Will it in general run better if the timing is set closer to TDC? or will it run better advanced as far as possible without pinging?

Thanks.

I have just rebuilt the carb, replaced the fuel pump, replaced the distributer, installed an electronic ignition unit.

The hesitation seems to be at least in part a function of the timing.

I set the timing to 6 deg BTDC as the manual says. Still does it. I just reset it to 10deg and I am about to test drive it.

The question is how critical is the timing setting if the engine is not pinging?

Will it in general run better if the timing is set closer to TDC? or will it run better advanced as far as possible without pinging?

Thanks.

#2

Timing is critical. Its best to advance the timing (initial) as far as possible, maintaining a smooth idle...when you find the point where it pings under load, back the timing down 2 degrees (at a time) until there no pinging heard.

#3

The 292 has a two part rubber-lined vibration damper that is prone to slippage, this makes the markings on the damper impossible to read accurately. A second issue is that a stock distributor advance curve is pretty stiff.

Setting the (initial) crankshaft timing is just part of the engine tuning. A vacuum gauge is a good way to set the initial timing until the damper can be replaced.

Setting the (initial) crankshaft timing is just part of the engine tuning. A vacuum gauge is a good way to set the initial timing until the damper can be replaced.

#4

That's really a vague question. I'd say as long as you have no driveability problems, it is not critical. However, if it is not tuned, you leave economy, performance, and overall enjoyability on the table. So it is absolutely worthwhile to tune the timing.

In general, any engine will like more initial advance, like around 12 degrees and maybe more but it should run fine at a factory setting if the engine is stock. On top of that, the amount and rate of mechanical and vacuum advance are important.

The part about stalling at a left turn doesn't sound like timing, though. That sounds like a fuel distribution problem. For most people, rebuilding a carb is buying a kit, cleanup, replacing stuff and throwing it back together. That's not what I would say is rebuilt but it's not necessarily bad, either. We diy-ers often miss things that seasoned experts might see. I might have a second look at the carburetor, particularly the accelerator pump since it occurs from a stop.

All these parts that you have changed, were they done in an attempt to fix this problem? Or, did the problem occur after installing one of them?

I'm with Tedster. Forget your timing marks unless you are certain that the damper is good. Advance it and see if the problem goes away.

In general, any engine will like more initial advance, like around 12 degrees and maybe more but it should run fine at a factory setting if the engine is stock. On top of that, the amount and rate of mechanical and vacuum advance are important.

The part about stalling at a left turn doesn't sound like timing, though. That sounds like a fuel distribution problem. For most people, rebuilding a carb is buying a kit, cleanup, replacing stuff and throwing it back together. That's not what I would say is rebuilt but it's not necessarily bad, either. We diy-ers often miss things that seasoned experts might see. I might have a second look at the carburetor, particularly the accelerator pump since it occurs from a stop.

All these parts that you have changed, were they done in an attempt to fix this problem? Or, did the problem occur after installing one of them?

I'm with Tedster. Forget your timing marks unless you are certain that the damper is good. Advance it and see if the problem goes away.

#5

That's really a vague question. I'd say as long as you have no driveability problems, it is not critical. However, if it is not tuned, you leave economy, performance, and overall enjoyability on the table. So it is absolutely worthwhile to tune the timing.

In general, any engine will like more initial advance, like around 12 degrees and maybe more but it should run fine at a factory setting if the engine is stock. On top of that, the amount and rate of mechanical and vacuum advance are important.

The part about stalling at a left turn doesn't sound like timing, though. That sounds like a fuel distribution problem. For most people, rebuilding a carb is buying a kit, cleanup, replacing stuff and throwing it back together. That's not what I would say is rebuilt but it's not necessarily bad, either. We diy-ers often miss things that seasoned experts might see. I might have a second look at the carburetor, particularly the accelerator pump since it occurs from a stop.

All these parts that you have changed, were they done in an attempt to fix this problem? Or, did the problem occur after installing one of them?

I'm with Tedster. Forget your timing marks unless you are certain that the damper is good. Advance it and see if the problem goes away.

In general, any engine will like more initial advance, like around 12 degrees and maybe more but it should run fine at a factory setting if the engine is stock. On top of that, the amount and rate of mechanical and vacuum advance are important.

The part about stalling at a left turn doesn't sound like timing, though. That sounds like a fuel distribution problem. For most people, rebuilding a carb is buying a kit, cleanup, replacing stuff and throwing it back together. That's not what I would say is rebuilt but it's not necessarily bad, either. We diy-ers often miss things that seasoned experts might see. I might have a second look at the carburetor, particularly the accelerator pump since it occurs from a stop.

All these parts that you have changed, were they done in an attempt to fix this problem? Or, did the problem occur after installing one of them?

I'm with Tedster. Forget your timing marks unless you are certain that the damper is good. Advance it and see if the problem goes away.

#6

Back when dirt was new, we had, or my oldest sis had a '57 Victoria 2-dr hardtop with a 292 & Ford-O-Matic. It would hesitate and stall upon acceleration unless you really tromped on the gas pedal.

The cure was to add some washers in the vacuum advance behind the spring, making the vacuum advance a tad slower. It didn't take many flat washers to have the desired effect.

tom

The cure was to add some washers in the vacuum advance behind the spring, making the vacuum advance a tad slower. It didn't take many flat washers to have the desired effect.

tom

#7

The 292 has a two part rubber-lined vibration damper that is prone to slippage, this makes the markings on the damper impossible to read accurately. A second issue is that a stock distributor advance curve is pretty stiff.

Setting the (initial) crankshaft timing is just part of the engine tuning. A vacuum gauge is a good way to set the initial timing until the damper can be replaced.

Setting the (initial) crankshaft timing is just part of the engine tuning. A vacuum gauge is a good way to set the initial timing until the damper can be replaced.

What does stiff mean in terms of advance curve? Does that mean it is likely to stall?

Trending Topics

#8

That's really a vague question. I'd say as long as you have no driveability problems, it is not critical. However, if it is not tuned, you leave economy, performance, and overall enjoyability on the table. So it is absolutely worthwhile to tune the timing.

I do have a problem with what you call "overall enjoyability" It just isn't fun to drive when it bucks, hesitates and sometimes stalls

In general, any engine will like more initial advance, like around 12 degrees and maybe more but it should run fine at a factory setting if the engine is stock. On top of that, the amount and rate of mechanical and vacuum advance are important.

The part about stalling at a left turn doesn't sound like timing, though.

I meant when you come to a stop waiting for traffic before making a left, not just any left turn. The condition is that same as a stop sign, just even more dangerous to stall in front of oncoming traffic.

That sounds like a fuel distribution problem. For most people, rebuilding a carb is buying a kit, cleanup, replacing stuff and throwing it back together. That's not what I would say is rebuilt but it's not necessarily bad, either. We diy-ers often miss things that seasoned experts might see. I might have a second look at the carburetor, particularly the accelerator pump since it occurs from a stop.

I bought the truck about 6 years ago and I was having more of less this problem then. I have spent the entire time since then hunting for an answer. I replaced the Carb as one of my first tries. I just got back from my test drive after setting the timing to 10 deg. No ping, but I still get hesitation, except when the the choke is applied. With the choke on, it runs better.

All these parts that you have changed, were they done in an attempt to fix this problem? Or, did the problem occur after installing one of them?

I'm with Tedster. Forget your timing marks unless you are certain that the damper is good. Advance it and see if the problem goes away.

I do have a problem with what you call "overall enjoyability" It just isn't fun to drive when it bucks, hesitates and sometimes stalls

In general, any engine will like more initial advance, like around 12 degrees and maybe more but it should run fine at a factory setting if the engine is stock. On top of that, the amount and rate of mechanical and vacuum advance are important.

The part about stalling at a left turn doesn't sound like timing, though.

I meant when you come to a stop waiting for traffic before making a left, not just any left turn. The condition is that same as a stop sign, just even more dangerous to stall in front of oncoming traffic.

That sounds like a fuel distribution problem. For most people, rebuilding a carb is buying a kit, cleanup, replacing stuff and throwing it back together. That's not what I would say is rebuilt but it's not necessarily bad, either. We diy-ers often miss things that seasoned experts might see. I might have a second look at the carburetor, particularly the accelerator pump since it occurs from a stop.

I bought the truck about 6 years ago and I was having more of less this problem then. I have spent the entire time since then hunting for an answer. I replaced the Carb as one of my first tries. I just got back from my test drive after setting the timing to 10 deg. No ping, but I still get hesitation, except when the the choke is applied. With the choke on, it runs better.

All these parts that you have changed, were they done in an attempt to fix this problem? Or, did the problem occur after installing one of them?

I'm with Tedster. Forget your timing marks unless you are certain that the damper is good. Advance it and see if the problem goes away.

#9

Back when dirt was new, we had, or my oldest sis had a '57 Victoria 2-dr hardtop with a 292 & Ford-O-Matic. It would hesitate and stall upon acceleration unless you really tromped on the gas pedal.

The cure was to add some washers in the vacuum advance behind the spring, making the vacuum advance a tad slower. It didn't take many flat washers to have the desired effect.

tom

The cure was to add some washers in the vacuum advance behind the spring, making the vacuum advance a tad slower. It didn't take many flat washers to have the desired effect.

tom

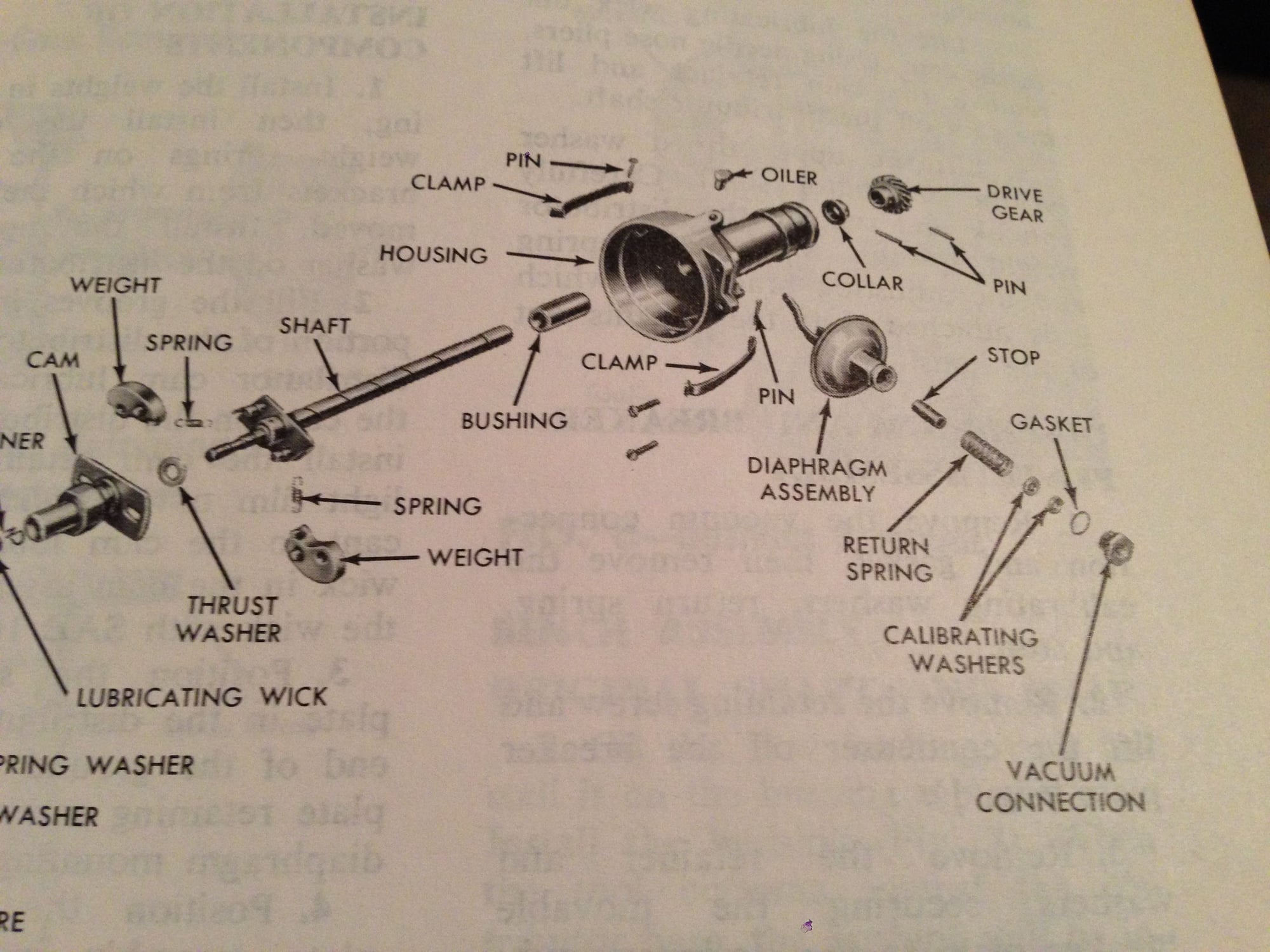

The service manual has this image showing a spring and "calibrating washers"

My distributor does not have those parts on the vacuum advance. Do I have the wrong advance mechanism?

#10

There are a whole bunch of threads here at FTE in the archives to digest if you're willing to spend some time getting up to speed on timing, as well as other webpages devoted specifically to ignition timing/distributor curving and such.

And a stock setup 292 Y block will respond really well to this. But it takes a methodical approach. At least you can eliminate this as the source of the problem and have a lot more fun too, better fuel economy (such as it is) and the Y block engine exhaust note is basically ear candy. Really!

Run it up to 3000 RPM or so with vac adv. disconnected and plugged, observe marks with a timing light. Report what the total timing is in degrees. Should be "all in", 36 to 38 degrees. Since you replaced the distributor itself it should be in good shape, but the mechanical advance may be too late. When the advance kicks in is more important than how much to some... degree.

And a stock setup 292 Y block will respond really well to this. But it takes a methodical approach. At least you can eliminate this as the source of the problem and have a lot more fun too, better fuel economy (such as it is) and the Y block engine exhaust note is basically ear candy. Really!

Run it up to 3000 RPM or so with vac adv. disconnected and plugged, observe marks with a timing light. Report what the total timing is in degrees. Should be "all in", 36 to 38 degrees. Since you replaced the distributor itself it should be in good shape, but the mechanical advance may be too late. When the advance kicks in is more important than how much to some... degree.

#11

Since you have a rebuilt distributor, it probably does not have a stock vacuum advance unit so it probably cannot be adjusted with washers. It probably can be adjusted with an allen wrench. I can't tell which one you have from your picture. It's very blury. However, vacuum advance is not a necessity. It is for economy and that's about it. You can disconnect and plug the vacuum line to see if the problem goes away.

The stock "stiff" advance curve would not cause it to stall.

It sounds a lot like you're not very familiar with diagnosing problems and you need to learn how to do that. A great place to start is with a shop manual. The factory shop manuals are excellent. If you don't already have a factory manual, either original or reprint, get one. And do what Tedster says to learn about stuff.

The stock "stiff" advance curve would not cause it to stall.

It sounds a lot like you're not very familiar with diagnosing problems and you need to learn how to do that. A great place to start is with a shop manual. The factory shop manuals are excellent. If you don't already have a factory manual, either original or reprint, get one. And do what Tedster says to learn about stuff.

#12

Plus one on the above.

I will add that your report that adding choke makes it less hesitant to stall may indicate that your accelerator pump may be set to lean or inoperative. If you watch down the venturi of the carb, does the carb put squirt of gas in when you first push on the throttle lever? If not, check the accelerator pump. If so, you may be able to adjust the pump to come into play earlier or more strongly.

When you step on the gas pedal, the air is moving and will accelerate and get sucked into the intake rather quickly. The fuel, on the other hand, will NOT accelerate as quicky as its mass is more dense. The accelerator pump adds a squirt of extra fuel to help make up for the slow acceleration of the liquid fuel through the carb passages. It 'bridges' the time it takes for the fuel to catch up to the air flow. If weak, you will get stumble on acceleration as the mix is not rich enough to burn.

tom

I will add that your report that adding choke makes it less hesitant to stall may indicate that your accelerator pump may be set to lean or inoperative. If you watch down the venturi of the carb, does the carb put squirt of gas in when you first push on the throttle lever? If not, check the accelerator pump. If so, you may be able to adjust the pump to come into play earlier or more strongly.

When you step on the gas pedal, the air is moving and will accelerate and get sucked into the intake rather quickly. The fuel, on the other hand, will NOT accelerate as quicky as its mass is more dense. The accelerator pump adds a squirt of extra fuel to help make up for the slow acceleration of the liquid fuel through the carb passages. It 'bridges' the time it takes for the fuel to catch up to the air flow. If weak, you will get stumble on acceleration as the mix is not rich enough to burn.

tom

#13

Plus one on the above.

I will add that your report that adding choke makes it less hesitant to stall may indicate that your accelerator pump may be set to lean or inoperative. If you watch down the venturi of the carb, does the carb put squirt of gas in when you first push on the throttle lever? If not, check the accelerator pump. If so, you may be able to adjust the pump to come into play earlier or more strongly.

When you step on the gas pedal, the air is moving and will accelerate and get sucked into the intake rather quickly. The fuel, on the other hand, will NOT accelerate as quicky as its mass is more dense. The accelerator pump adds a squirt of extra fuel to help make up for the slow acceleration of the liquid fuel through the carb passages. It 'bridges' the time it takes for the fuel to catch up to the air flow. If weak, you will get stumble on acceleration as the mix is not rich enough to burn.

tom

I will add that your report that adding choke makes it less hesitant to stall may indicate that your accelerator pump may be set to lean or inoperative. If you watch down the venturi of the carb, does the carb put squirt of gas in when you first push on the throttle lever? If not, check the accelerator pump. If so, you may be able to adjust the pump to come into play earlier or more strongly.

When you step on the gas pedal, the air is moving and will accelerate and get sucked into the intake rather quickly. The fuel, on the other hand, will NOT accelerate as quicky as its mass is more dense. The accelerator pump adds a squirt of extra fuel to help make up for the slow acceleration of the liquid fuel through the carb passages. It 'bridges' the time it takes for the fuel to catch up to the air flow. If weak, you will get stumble on acceleration as the mix is not rich enough to burn.

tom

I have also tried this morning to advance the timing as far as it will go. The vacuum advance keeps it from moving any further clockwise. That did not solve the problem.

#14

There are a whole bunch of threads here at FTE in the archives to digest if you're willing to spend some time getting up to speed on timing, as well as other webpages devoted specifically to ignition timing/distributor curving and such.

And a stock setup 292 Y block will respond really well to this. But it takes a methodical approach. At least you can eliminate this as the source of the problem and have a lot more fun too, better fuel economy (such as it is) and the Y block engine exhaust note is basically ear candy. Really!

Run it up to 3000 RPM or so with vac adv. disconnected and plugged, observe marks with a timing light. Report what the total timing is in degrees. Should be "all in", 36 to 38 degrees. Since you replaced the distributor itself it should be in good shape, but the mechanical advance may be too late. When the advance kicks in is more important than how much to some... degree.

And a stock setup 292 Y block will respond really well to this. But it takes a methodical approach. At least you can eliminate this as the source of the problem and have a lot more fun too, better fuel economy (such as it is) and the Y block engine exhaust note is basically ear candy. Really!

Run it up to 3000 RPM or so with vac adv. disconnected and plugged, observe marks with a timing light. Report what the total timing is in degrees. Should be "all in", 36 to 38 degrees. Since you replaced the distributor itself it should be in good shape, but the mechanical advance may be too late. When the advance kicks in is more important than how much to some... degree.

#15

wfon said: I have also tried this morning to advance the timing as far as it will go. The vacuum advance keeps it from moving any further clockwise. That did not solve the problem.

Note rotor and bowl positions, remove distributor hold-down & bolt. Pull distributor and rotate the bowl so there is more room for the vacuum advance, and turn the rotor in the same direction a tooth or two. Put distributor back in place, and add some tension to the hold down {slight}. Adjust plug wires one spot in the proper direction in the cap to get the pointer back at the plug/wire it was pointing at when removed, or turn the bowl.

Crank engine a few turns to seat the distributor hex on the oil pump drive. The distributor will drop in place as the load of the oil pump causes a bit of slippage. Set timing.

Note rotor and bowl positions, remove distributor hold-down & bolt. Pull distributor and rotate the bowl so there is more room for the vacuum advance, and turn the rotor in the same direction a tooth or two. Put distributor back in place, and add some tension to the hold down {slight}. Adjust plug wires one spot in the proper direction in the cap to get the pointer back at the plug/wire it was pointing at when removed, or turn the bowl.

Crank engine a few turns to seat the distributor hex on the oil pump drive. The distributor will drop in place as the load of the oil pump causes a bit of slippage. Set timing.