7.3 Diesel - WVO advice

#1

7.3 Diesel - WVO advice

Hello all.

I'm going to put a WVO system in my truck. I have tried to dig up as many posts as I can on the internet and I'm a bit confused.

I have a 2001 F350 7.3 Diesel with a Riff Raff Regulated Return.

I took a look at http://www.wvodesigns.com/wiki/1999-...9-2002_7.3_PSD and the system looks very simple but it will not work with my setup as I have the regulated return.

Option #1 -

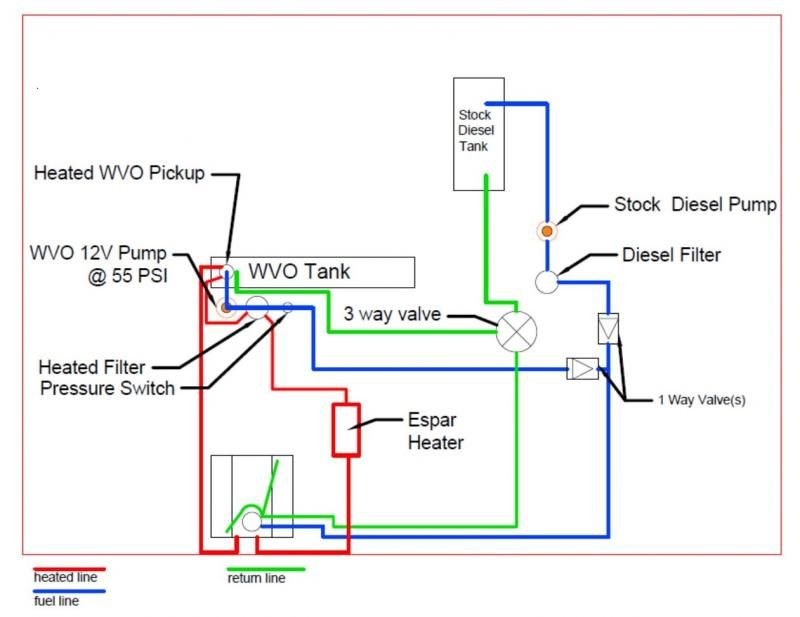

I was thinking about going the other way, removing the fuel bowl filter (build a dummy if needed), installing a post filter after the stock pump (for diesel starting operation) and installing a 3 way valve on the return line (for purge function). I think I would have to run my purge for a bit longer then 30 seconds if I did this as there is quite a bit of volume in the fuel bowl.

Option #2 - get rid of the Riff Raff Regulated Return (but I like it as I know my #8 injector isn't being starved.) and go with the http://www.wvodesigns.com/wiki/1999-...9-2002_7.3_PSD design.

I'll attach a drawing the next post for Option #1

any ideas?

I'm going to put a WVO system in my truck. I have tried to dig up as many posts as I can on the internet and I'm a bit confused.

I have a 2001 F350 7.3 Diesel with a Riff Raff Regulated Return.

I took a look at http://www.wvodesigns.com/wiki/1999-...9-2002_7.3_PSD and the system looks very simple but it will not work with my setup as I have the regulated return.

Option #1 -

I was thinking about going the other way, removing the fuel bowl filter (build a dummy if needed), installing a post filter after the stock pump (for diesel starting operation) and installing a 3 way valve on the return line (for purge function). I think I would have to run my purge for a bit longer then 30 seconds if I did this as there is quite a bit of volume in the fuel bowl.

Option #2 - get rid of the Riff Raff Regulated Return (but I like it as I know my #8 injector isn't being starved.) and go with the http://www.wvodesigns.com/wiki/1999-...9-2002_7.3_PSD design.

I'll attach a drawing the next post for Option #1

any ideas?

#3

want you want really, is a 2-tank, 2-delivery system. THEE ONLY thing, you want the wvo and D2 to share, is the heads/motor.

Having the FRx, your ahead of the game. I'm using mine to feed just that, WVO. Remove the d2 fuel lines at heads ,and install checkvalves..(wvo designs). Then, re-install d2 fuel lines on cv's.

Other then that, you can foolow the wvo designs "wvo plumbing" and be done. TiT / TiH assy, running along frame to heat wvo up. Hotfox or another type of wvo tank with the heating assy pre-mounted inside.

The new wvodesigns pump is cool. I got one. Its built-in regulated pressure gives you room for psi, which also ,regulates internally . So really, no "return" line anywhere on system. Or, the $38.00 ones from ebay have been known to withstand the heated wvo. Got one on the burner, for the JIC..(just in case).

. So really, no "return" line anywhere on system. Or, the $38.00 ones from ebay have been known to withstand the heated wvo. Got one on the burner, for the JIC..(just in case).

Having the FRx, your ahead of the game. I'm using mine to feed just that, WVO. Remove the d2 fuel lines at heads ,and install checkvalves..(wvo designs). Then, re-install d2 fuel lines on cv's.

Other then that, you can foolow the wvo designs "wvo plumbing" and be done. TiT / TiH assy, running along frame to heat wvo up. Hotfox or another type of wvo tank with the heating assy pre-mounted inside.

The new wvodesigns pump is cool. I got one. Its built-in regulated pressure gives you room for psi, which also ,regulates internally

. So really, no "return" line anywhere on system. Or, the $38.00 ones from ebay have been known to withstand the heated wvo. Got one on the burner, for the JIC..(just in case).

. So really, no "return" line anywhere on system. Or, the $38.00 ones from ebay have been known to withstand the heated wvo. Got one on the burner, for the JIC..(just in case).

#4

request for clarity?

Ok, so I'm crystal clear. What your suggesting is to remove the regulated return system and replaced it with check valves, just like the system in the WVO design? Or is there a way to keep the regulated return system (or does it just get too complicated).

Cheers,

josh

Cheers,

josh

#5

ok, you'll want to leave the FRx in place, BUT, remove line from the "T" in the FRx, going to the FPR on the stock fuel bowl. You'll use the FRx lines to feed the wvo to the heads. The stock D2 lines will need cv's at the heads to keep wvo from backflushing into the D2 tank.

To keep D2 from filling up the wvo tank, thats where another cv will come into play along with a purge valve to help "flush" wvo back into wvo tank via D2....

https://www.ford-trucks.com/forums/m...ut-137436.html

To keep D2 from filling up the wvo tank, thats where another cv will come into play along with a purge valve to help "flush" wvo back into wvo tank via D2....

https://www.ford-trucks.com/forums/m...ut-137436.html

#6

Reg Return, Frx, etc NOT NEEDED. Sell it to some other sucker who will think its a good idea...

Like Tim said, you want redundant and segregated fuel systems. The Vegistroke design, poorly copied by wvodesigns plans is by far the simplest and most reliable way to do this.

Leave the stock system 100% stock, except to add CV's between the fuel filter and the heads. Wvo and svo diesel to vegetable oil conversion kit | VeggieGarage.com has developed a CV kit that replaces the factory fuel lines with ptfe-lines SS braided hoses and puts larger, more durable CV's up by the filter (insuring you never have to go to the PITA fitting on rear on pass-side head again). Or, just use the little CV's that screw directly into the heads.

Then, supply VO to the heads using the test ports where Frx is now. I dunno if it matters at stock power levels - but I use much bigger hoses than the Frx has... The VO system will look like the OE fuel system with a tank, pre-filter, fuel pump, FPR, primary filter, CV and a 12v solenoid valve for 'purge'.

I prefer to use an OE-type 7.3 PSD fuel pump and an external FPR like the Magnafuel 9925. This economical set-up offers stellar performance and in the event you did have a pump failure - you can simply replace it in the parking lot of the nearest autoparts store.

The other reason I prefer an external FPR is because I use TIH for the supply from tank to pump and from FPR 'return'. Instead of dumping this HOT fuel back into the tank, I tee it into the supply line from the tank and create a 'loop' for the fuel to travel thru. This dramatically increases the fuel temp (BEFORE the pump and filters, where we need it the most) and also greatly reduces the strain on the pump.

So, VO tank, TIH to pre-filter, pump, FPR - the regulated fuel leaves FPR and goes into the primary VO filter (6-10mic absolute) and to a CV. After the CV is a tee, one side goes up to the heads, the 'purge' valve is on the other side. There will be a line from purge valve to tank.

The prefilter should be no finer than 50 microns, but 150 microns is ideal. DO NOT use a 'fine' filter before the pump - it will kill the pump.

I also recommend a heated fuel pick-up in the tank and 'wrapping' the VO filter with 3/8" copper tubing and running coolant thru it. This will provide more than adequate heat to 'melt' any crisco or bacon fat in the filter! A coolant pump is a good idea anyway, but will insure ya get adequate coolant flow thru the VO loop with this 'restriction'.

In operation, you start up on diesel and when the engine gets to operating temp, flip the VO pump on and the D2 pump off - now yer greasin'!!! When ya get where you're going, turn the D2 pump on, the VO pump off and open the purge valve for 10-15 seconds - then let the engine idle another minute or so and you will have flushed ALL of the VO out of the heads and injectors.

This proven design is sooooo simple and non-invasive I often have mechanics ask me 'where is this veggie-conversion?'. There is just nothing to see (or get in the way of regular maintenance) under the hood. I have helped a couple dozen people do PSD conversions this way and they all work flawlessly.

Oh, I'm not recommending the $40 pumps anymore. We've had a few failures recently - I think they may have changed something or maybe the dies are just getting worn out... Either way, we can get OEM Bosch pumps for under $150 these days and they are a MUCH higher quality pump. The $40 pumps work though, and some may find they'd rather buy (2) and just change them out IF they fail. I've been using an Airtex pump (autozone, oriellys, etc) for most of the 180k miles on my dually's VO system - but they cost more than we can get the bigger (better?) Bosch for now.

I really need to sit down and sketch up a nice drawing for this design one of these days......................

Good luck and keep us posted! Lemme know if ya have any questions - I'm happy to help.

Like Tim said, you want redundant and segregated fuel systems. The Vegistroke design, poorly copied by wvodesigns plans is by far the simplest and most reliable way to do this.

Leave the stock system 100% stock, except to add CV's between the fuel filter and the heads. Wvo and svo diesel to vegetable oil conversion kit | VeggieGarage.com has developed a CV kit that replaces the factory fuel lines with ptfe-lines SS braided hoses and puts larger, more durable CV's up by the filter (insuring you never have to go to the PITA fitting on rear on pass-side head again). Or, just use the little CV's that screw directly into the heads.

Then, supply VO to the heads using the test ports where Frx is now. I dunno if it matters at stock power levels - but I use much bigger hoses than the Frx has... The VO system will look like the OE fuel system with a tank, pre-filter, fuel pump, FPR, primary filter, CV and a 12v solenoid valve for 'purge'.

I prefer to use an OE-type 7.3 PSD fuel pump and an external FPR like the Magnafuel 9925. This economical set-up offers stellar performance and in the event you did have a pump failure - you can simply replace it in the parking lot of the nearest autoparts store.

The other reason I prefer an external FPR is because I use TIH for the supply from tank to pump and from FPR 'return'. Instead of dumping this HOT fuel back into the tank, I tee it into the supply line from the tank and create a 'loop' for the fuel to travel thru. This dramatically increases the fuel temp (BEFORE the pump and filters, where we need it the most) and also greatly reduces the strain on the pump.

So, VO tank, TIH to pre-filter, pump, FPR - the regulated fuel leaves FPR and goes into the primary VO filter (6-10mic absolute) and to a CV. After the CV is a tee, one side goes up to the heads, the 'purge' valve is on the other side. There will be a line from purge valve to tank.

The prefilter should be no finer than 50 microns, but 150 microns is ideal. DO NOT use a 'fine' filter before the pump - it will kill the pump.

I also recommend a heated fuel pick-up in the tank and 'wrapping' the VO filter with 3/8" copper tubing and running coolant thru it. This will provide more than adequate heat to 'melt' any crisco or bacon fat in the filter! A coolant pump is a good idea anyway, but will insure ya get adequate coolant flow thru the VO loop with this 'restriction'.

In operation, you start up on diesel and when the engine gets to operating temp, flip the VO pump on and the D2 pump off - now yer greasin'!!! When ya get where you're going, turn the D2 pump on, the VO pump off and open the purge valve for 10-15 seconds - then let the engine idle another minute or so and you will have flushed ALL of the VO out of the heads and injectors.

This proven design is sooooo simple and non-invasive I often have mechanics ask me 'where is this veggie-conversion?'. There is just nothing to see (or get in the way of regular maintenance) under the hood. I have helped a couple dozen people do PSD conversions this way and they all work flawlessly.

Oh, I'm not recommending the $40 pumps anymore. We've had a few failures recently - I think they may have changed something or maybe the dies are just getting worn out... Either way, we can get OEM Bosch pumps for under $150 these days and they are a MUCH higher quality pump. The $40 pumps work though, and some may find they'd rather buy (2) and just change them out IF they fail. I've been using an Airtex pump (autozone, oriellys, etc) for most of the 180k miles on my dually's VO system - but they cost more than we can get the bigger (better?) Bosch for now.

I really need to sit down and sketch up a nice drawing for this design one of these days......................

Good luck and keep us posted! Lemme know if ya have any questions - I'm happy to help.

#7

Trending Topics

#8

Hi guys. I didn't want to hijack this thread but I believe my question will add value to this here for somebody.

SkiskiJason, you prefer a superduty pump for wvo. I plan on doing a system very similar to yours and I believe in the sd pump for its pressure capability and reliability. I have heard that the sd pump will only last a long time if it is flushed with diesel after switching from vo to diesel. Is there truth to that?

You have written many helpful things in this thread and other forums. I appreciate your advice and would be interested to see your take on flushing the sd pump and if it's needed.

SkiskiJason, you prefer a superduty pump for wvo. I plan on doing a system very similar to yours and I believe in the sd pump for its pressure capability and reliability. I have heard that the sd pump will only last a long time if it is flushed with diesel after switching from vo to diesel. Is there truth to that?

You have written many helpful things in this thread and other forums. I appreciate your advice and would be interested to see your take on flushing the sd pump and if it's needed.

#9

Hi guys. I didn't want to hijack this thread but I believe my question will add value to this here for somebody.

SkiskiJason, you prefer a superduty pump for wvo. I plan on doing a system very similar to yours and I believe in the sd pump for its pressure capability and reliability. I have heard that the sd pump will only last a long time if it is flushed with diesel after switching from vo to diesel. Is there truth to that?

You have written many helpful things in this thread and other forums. I appreciate your advice and would be interested to see your take on flushing the sd pump and if it's needed.

SkiskiJason, you prefer a superduty pump for wvo. I plan on doing a system very similar to yours and I believe in the sd pump for its pressure capability and reliability. I have heard that the sd pump will only last a long time if it is flushed with diesel after switching from vo to diesel. Is there truth to that?

You have written many helpful things in this thread and other forums. I appreciate your advice and would be interested to see your take on flushing the sd pump and if it's needed.

I do not flush my SD pump. It is full of WVO all the time. This would probably cause more problems on a truck that was used less than mine. From what I can tell, the oil does not have time to polymerize in the pump.

I met a number of people with failed PSD pumps when I first started - all warning me mine was gonna quit. Turns out, most were trying to suck cold oil thru a primary-type filter - and the rest decided no pre-pump filter was needed. The key may be using a properly sized pre-pump filter (100-150mic) and adequately heating the WVO to reduce viscosity and strain on the pump. The 144 micron Donaldson P550974 works great. 'Looping' the return from FPR in heated fuel line is also HUGE for making the PSD pump work.

Veggie Garage LLC: Donaldson 144 Micron Screen Pre Filter

Thread

Thread Starter

Forum

Replies

Last Post

sean23johnson

Bio-diesel, Propane & Alternative Diesel Engine Fuels

37

01-16-2015 01:43 PM

Hotwheelbill

Bio-diesel, Propane & Alternative Diesel Engine Fuels

3

05-29-2006 05:08 PM

Lushman

1999 - 2003 7.3L Power Stroke Diesel

18

05-04-2006 07:48 AM