HOWTO - Stop Me - Hydroboost Write Up

#1

Join Date: May 2009

Location: Bay Area, Unfortunately

Posts: 1,460

Likes: 0

Received 5 Likes

on

3 Posts

HOWTO - Stop Me - Hydroboost Write Up

Okay, I have been having problems with my brakes, which has been slowly getting worse. I would turn off my truck, come back 1/2 to 1 hour later and my brake pedal would be hard. As of the last few weeks, this has increased to 15 minutes for it to lose vacuum.

I wanted to upgrade to hydroboost eventually, and figured I could just do it now instead of replacing the vacuum booster and then upgrading down the road.

A hydroboost system uses pressure from the power steering pump to provide assist for the brakes. It provides a lot more pressure for the brakes. There are also negatives, with the biggest one being if you lose your power steering pump, you lose brake assist (after the reserve in the booster is lost). BUT if you lose the power steering pump, you lose the steering anyway and are not going anywhere. Also, once the reserves are gone in the booster, you still have better braking than you would with a vacuum booster once its reserves were gone (at least it feels that way to me).

Enough for the background, here we go!

You will need five distinct parts: The pressure hose going from the power steering pump to the hydroboost unit, the pressure hose going from the hydroboost unit to the steering box, The return hose from the hydroboost unit, the hydroboost specific reservoir, and the hydroboost unit itself. I got my parts off a late 80's, early 90's Super Duty. Now would also be a good time to get an o-ring seal kit for the power steering pump.

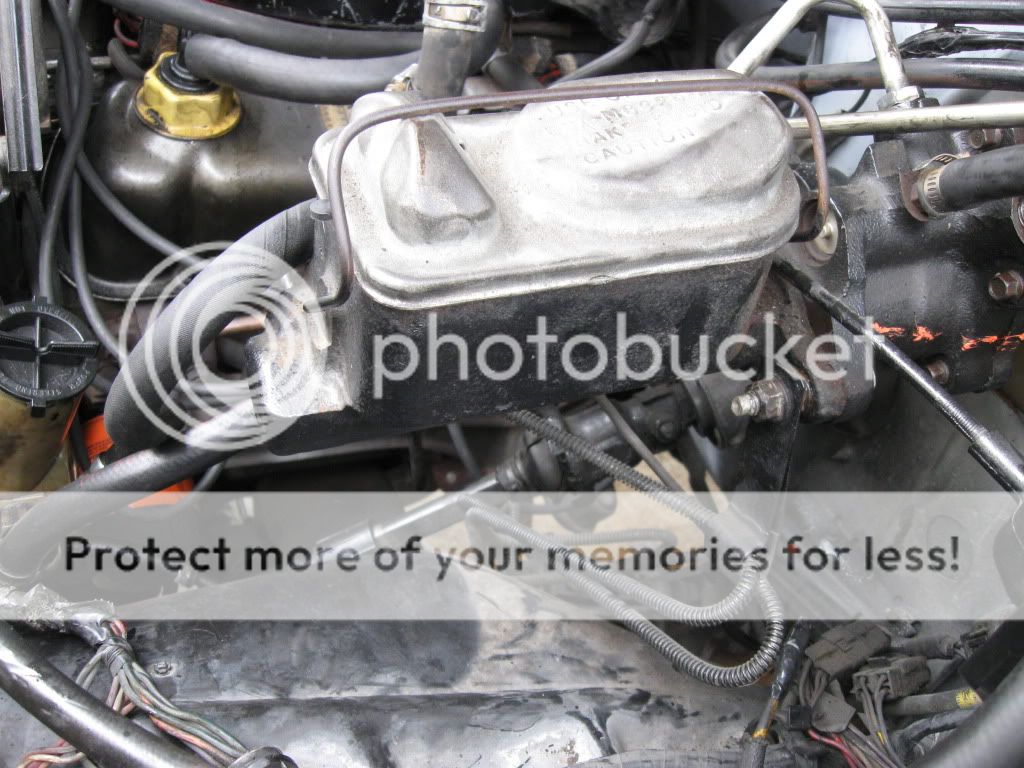

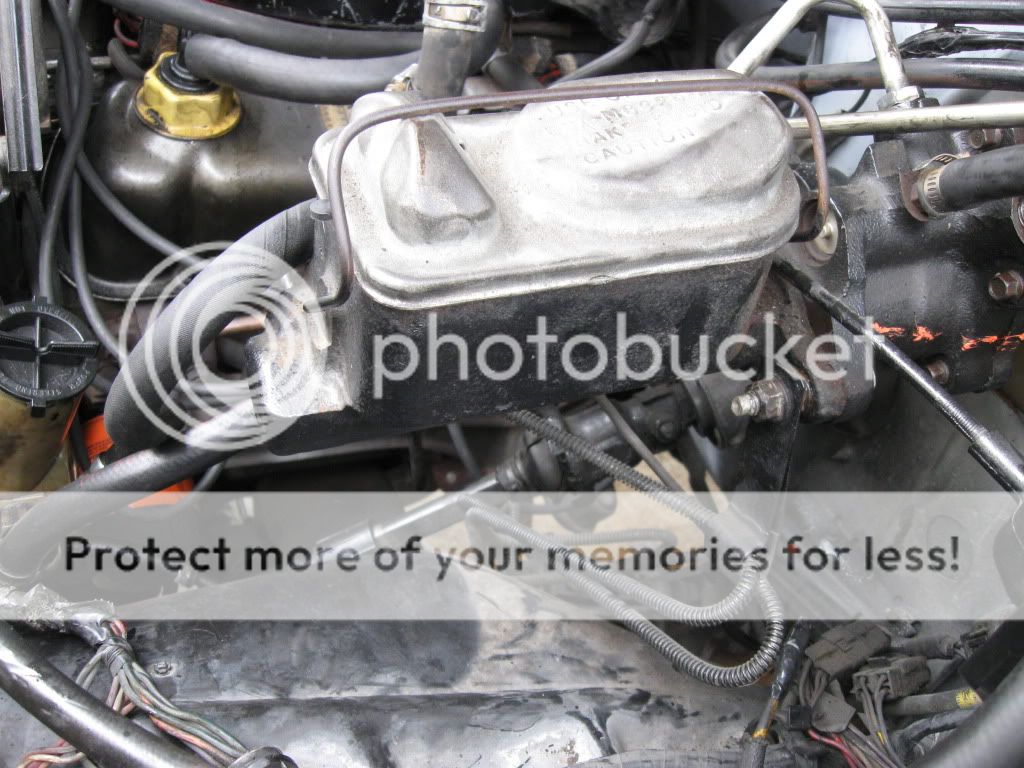

Here is what we started with. It is as simple as first taking off the master cylinder from the booster. 2 nuts hold the master cylinder to the booster, and one nut holds a bracket to the same studs. Slide the master cylinder forward. you do not need to disconnect the brake lines, but MAKE SURE the master cylinder is supported. Disconnect and block off the vacuum supply hose for the vacuum booster.

Now we move to the inside. Take off the cotter pin that retains the booster shaft to the pedat. Slide off the brake light switch and the bushings. Now you undo the 4 bolts that hold the booster to the firewall. Pull out the booster, and the old one is out!

Now we can do our install.

The new one bolts right in place of the old booster. The four bolts line up. Tighten those down from inside the truck. Next, mount the master cylinder to the booster unit, and tighten the nuts.

Now, lets move to the inside. I ran into a MINOR problem. The brake light switch did not line up. I put on the hydroboost shaft onto the pedal, but could not get the switch on. My solution - turn the switch 180 degrees. Now the U shaped part of the switch is on the outside instead of the inside. Put the bushings in, and the cotter pin and you are done with that part. You might need to adjust the cruise control switch, but that might vary.

Now, onto the last part - the power steering pump and reservoir.

Start by draining the old reservoir. There is no clean or pretty way to do this. Next, disconnect the original return line from the bottom. Disconnect the pressure line from the side. Remove the fitting from the side of the reservoir. Now, wiggle off the old reservoir. There is a large o-ring on the pump that seals to the reservoir. Now would be a good time to replace it. Of course, I did not. Lube up the o-ring and the inside of the reservoir with power steering fluid, and slide the reservoir onto the pump. Put the fitting you had taken off of the pump back on. It uses o-rings too. Now would be a good time to replace them. I did not, and had a little leakage.

Next, connect the lower return line to the reservoir. Connect the upper return line from the hydroboost unit to the reservoir. Now connect the pressure line from the power steering pump to the hydroboost unit. Last, remove the pressure line from the steering box. Connect the new pressure line from the hydroboost unit to the steering box. A lot of these lines use an o-ring on one end. make sure it is in good shape and lube it up before putting it in.

Now, fill the pump and bleed it.

You are now ready to go!

How does it work? Well, I almost sent my butt through my ears the first couple of times I hit the brakes! This is awesome. It is one of the best things I could have done for my brakes. On a side note, the truck also runs better since I no longer have the vacuum leak from the booster.

Hope this helps.

I wanted to upgrade to hydroboost eventually, and figured I could just do it now instead of replacing the vacuum booster and then upgrading down the road.

A hydroboost system uses pressure from the power steering pump to provide assist for the brakes. It provides a lot more pressure for the brakes. There are also negatives, with the biggest one being if you lose your power steering pump, you lose brake assist (after the reserve in the booster is lost). BUT if you lose the power steering pump, you lose the steering anyway and are not going anywhere. Also, once the reserves are gone in the booster, you still have better braking than you would with a vacuum booster once its reserves were gone (at least it feels that way to me).

Enough for the background, here we go!

You will need five distinct parts: The pressure hose going from the power steering pump to the hydroboost unit, the pressure hose going from the hydroboost unit to the steering box, The return hose from the hydroboost unit, the hydroboost specific reservoir, and the hydroboost unit itself. I got my parts off a late 80's, early 90's Super Duty. Now would also be a good time to get an o-ring seal kit for the power steering pump.

Here is what we started with. It is as simple as first taking off the master cylinder from the booster. 2 nuts hold the master cylinder to the booster, and one nut holds a bracket to the same studs. Slide the master cylinder forward. you do not need to disconnect the brake lines, but MAKE SURE the master cylinder is supported. Disconnect and block off the vacuum supply hose for the vacuum booster.

Now we move to the inside. Take off the cotter pin that retains the booster shaft to the pedat. Slide off the brake light switch and the bushings. Now you undo the 4 bolts that hold the booster to the firewall. Pull out the booster, and the old one is out!

Now we can do our install.

The new one bolts right in place of the old booster. The four bolts line up. Tighten those down from inside the truck. Next, mount the master cylinder to the booster unit, and tighten the nuts.

Now, lets move to the inside. I ran into a MINOR problem. The brake light switch did not line up. I put on the hydroboost shaft onto the pedal, but could not get the switch on. My solution - turn the switch 180 degrees. Now the U shaped part of the switch is on the outside instead of the inside. Put the bushings in, and the cotter pin and you are done with that part. You might need to adjust the cruise control switch, but that might vary.

Now, onto the last part - the power steering pump and reservoir.

Start by draining the old reservoir. There is no clean or pretty way to do this. Next, disconnect the original return line from the bottom. Disconnect the pressure line from the side. Remove the fitting from the side of the reservoir. Now, wiggle off the old reservoir. There is a large o-ring on the pump that seals to the reservoir. Now would be a good time to replace it. Of course, I did not. Lube up the o-ring and the inside of the reservoir with power steering fluid, and slide the reservoir onto the pump. Put the fitting you had taken off of the pump back on. It uses o-rings too. Now would be a good time to replace them. I did not, and had a little leakage.

Next, connect the lower return line to the reservoir. Connect the upper return line from the hydroboost unit to the reservoir. Now connect the pressure line from the power steering pump to the hydroboost unit. Last, remove the pressure line from the steering box. Connect the new pressure line from the hydroboost unit to the steering box. A lot of these lines use an o-ring on one end. make sure it is in good shape and lube it up before putting it in.

Now, fill the pump and bleed it.

You are now ready to go!

How does it work? Well, I almost sent my butt through my ears the first couple of times I hit the brakes! This is awesome. It is one of the best things I could have done for my brakes. On a side note, the truck also runs better since I no longer have the vacuum leak from the booster.

Hope this helps.

#7

Good write-up! I have two things to add tho:

1) if your truck has an aluminum master cylinder with a plastic reservoir, its bolt holeswill not line up with the studs on the hydroboost - you will need to take a small die-grinder to them and elongate them a bit towards the outside, we're talking about 1/16" each so nothing gets weakened by this procedure.

2) on certain trucks (IIRC the '92-'96) the hydrobost will bolt up to the firewall, but the linkage rod that connects it to the pedal will sit a very steep angle, which may actually bind the linkage. Solution to this would be grab the hydroboost-specific brake pedal, or simply grind the pin off your factory pedal and weld it a bit higher on the pedal.

1) if your truck has an aluminum master cylinder with a plastic reservoir, its bolt holeswill not line up with the studs on the hydroboost - you will need to take a small die-grinder to them and elongate them a bit towards the outside, we're talking about 1/16" each so nothing gets weakened by this procedure.

2) on certain trucks (IIRC the '92-'96) the hydrobost will bolt up to the firewall, but the linkage rod that connects it to the pedal will sit a very steep angle, which may actually bind the linkage. Solution to this would be grab the hydroboost-specific brake pedal, or simply grind the pin off your factory pedal and weld it a bit higher on the pedal.

Trending Topics

#9

I found conformation ... there are other folks out there saying the same thing.

Interestingly, they also state that this system leads to shorter stopping distances ... AND dramatic reduction of brake fade caused by multiple brake applications ... all because of the greater system pressure.

Some folks say that the increase can be as much as 400 PSI ... from about 800 to about 1200.

Wow.

But all this still leaves me with some questions:

Brake system pressure is a function of pistons pushing on a fluid ... and that fluid pressing on another piston.

The amount of pressure in the system ... is a result of the combination of pressure put on the first piston, the SIZE and sealing efficiency of the first piston ... and the SIZE and sealing efficiency of the second piston.

With the addition of this "pedal assist" ... you have not increased the the size or sealing efficiency of either piston ... you've increased the amount of force pushing on them. Which would increase system pressure.

a) Since you have more potential pressure in this system ... haven't you increased the risk of wheel lock up? I imagine this type of booster would work GREAT with an anti-lock brake system ... but without anti lock ... I wonder if this system is gonna be a handful in the rain. How hard is it to modulate the pedal to prevent wheel lockup? Especially with a light rear-ended Pick Up Truck!

b) Sealing efficiency. I can see disc brakes calipers standing up to the increased system pressures ... but rear wheel cylinders? Do they stand up to the pressure with out leaking?

This could be pretty cool ... I will be very interested to see your 60 - 180 day reports.

#10

Join Date: May 2009

Location: Bay Area, Unfortunately

Posts: 1,460

Likes: 0

Received 5 Likes

on

3 Posts

My other truck is 4 wheel disc with no proportioning valve. It is interesting in the rain. The F-250 locks up real quick. It is not much different, as I left the proportioning valve on, so the fronts still lock up first. There is a very brief period where you step on the brakes too hard at first, which almost sends you through the windshield. After that, you gauge how much pressure is is going to take on the pedal. As for changing piston size and such, I am contemplating throwing on the Super duty master, which has a 1 5/16" bore. I should have picked that up while I was there, but did not want to have to adapt brake lines and such (but my master is almost due for replacement, so that might be an upgrade that is coming up.

#12

Join Date: May 2009

Location: Bay Area, Unfortunately

Posts: 1,460

Likes: 0

Received 5 Likes

on

3 Posts

I am not sure, I think the only problem would be making sure the brackets fit the engine and the fitting ends matching up to the box. I would love to upgrade mine to a saginaw pump, but I can not find a hydroboost saginaw pump for a Ford. The Lincoln one might be worth picking up and trying.

#13

Join Date: Nov 2005

Location: Charles Town, W bygod Va

Posts: 7,437

Likes: 0

Received 3 Likes

on

3 Posts

I thought I saw a thread about this a while back and the general consencus was that the hydroboost wasnt really an upgrade unless you had enough cam to lose vaccum at lower rpms. As long as you can push the pedal hard enough to lock the wheels what more do you need? with the hydroboost if your engine stalls you lose power assist unlike vaccum assist where you get a few more brake applications.

#15

Join Date: May 2009

Location: Bay Area, Unfortunately

Posts: 1,460

Likes: 0

Received 5 Likes

on

3 Posts

I had already replaced the vacuum check valve and still had problems.

Actually, contrary to your last post, hydroboost also gives you reserves as with the vacuum assist in case you lose engine power. Once you run out of reserves, there is still a better pedal feel and you do not need as much effort to stop the truck as you would with a vacuum booster and pedal that is extremely hard. You also do not need to stand on the brakes to lock them up, as you do with vacuum brakes

It might not be for everybody, but I sure like it A LOT better than my vacuum set up. I feel the brakes are the most important system on a vehicle, and it does not hurt to go overkill on them.

Actually, contrary to your last post, hydroboost also gives you reserves as with the vacuum assist in case you lose engine power. Once you run out of reserves, there is still a better pedal feel and you do not need as much effort to stop the truck as you would with a vacuum booster and pedal that is extremely hard. You also do not need to stand on the brakes to lock them up, as you do with vacuum brakes

It might not be for everybody, but I sure like it A LOT better than my vacuum set up. I feel the brakes are the most important system on a vehicle, and it does not hurt to go overkill on them.